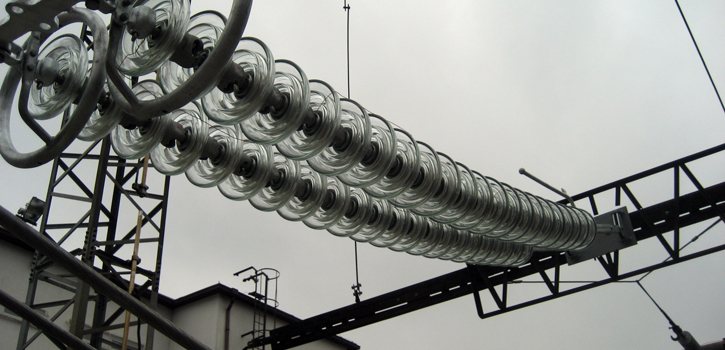

At Industrias Arruti we have extensive experience designing, developing and manufacturing hardware insulator strings for distribution and transmission lines.

When designing the strings and their components, it is important to take into account both the electrical and mechanical parameters.

From an electrical point of view, the line voltage and maximum short circuit intensity supported by the string are the most critical factors.

• The geometry of each component must be such that it prevents the appearance of the corona effect, thereby limiting the level of radio interference.

• Where necessary, the strings can be equipped with elements that are specially designed to standardise the electric field.

• The sections of pieces and the joints between must be studied to ensure the minimum guaranteed short circuit current.

From a mechanical point of view, in addition to guaranteeing the mechanical load specified by the client, other factors such as minimum working temperature or the corrosive level of the environment must also be considered:

• To ensure the proper mechanical load of all parts and minimise dispersion, quality control is critical during all phases of the manufacturing process and statistical controls of the data obtained.

• Very cold working environments require highly resilient materials.

• Finally, it is important to ascertain the local pollution or salinity level in order to propose appropriate and lasting protection.

There are two different lines of business within the conductor strings area:

• Distribution

• Transmission

° Standard conductors

° High capacity conductors